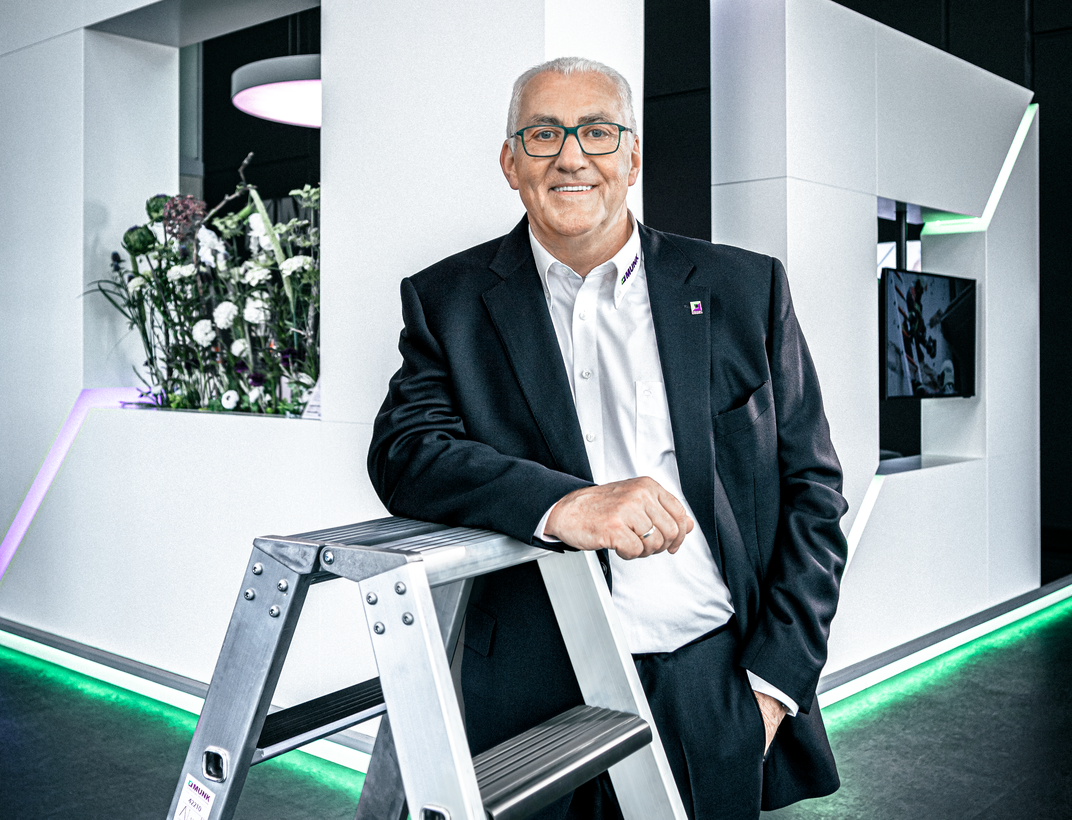

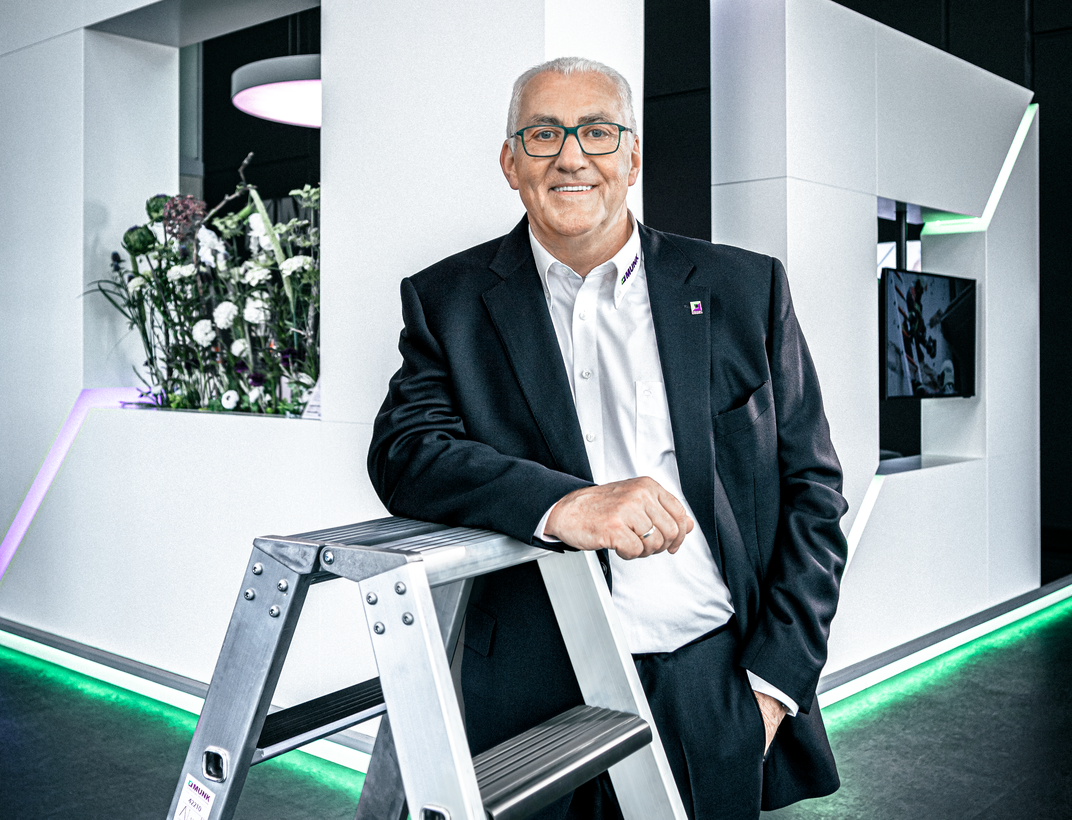

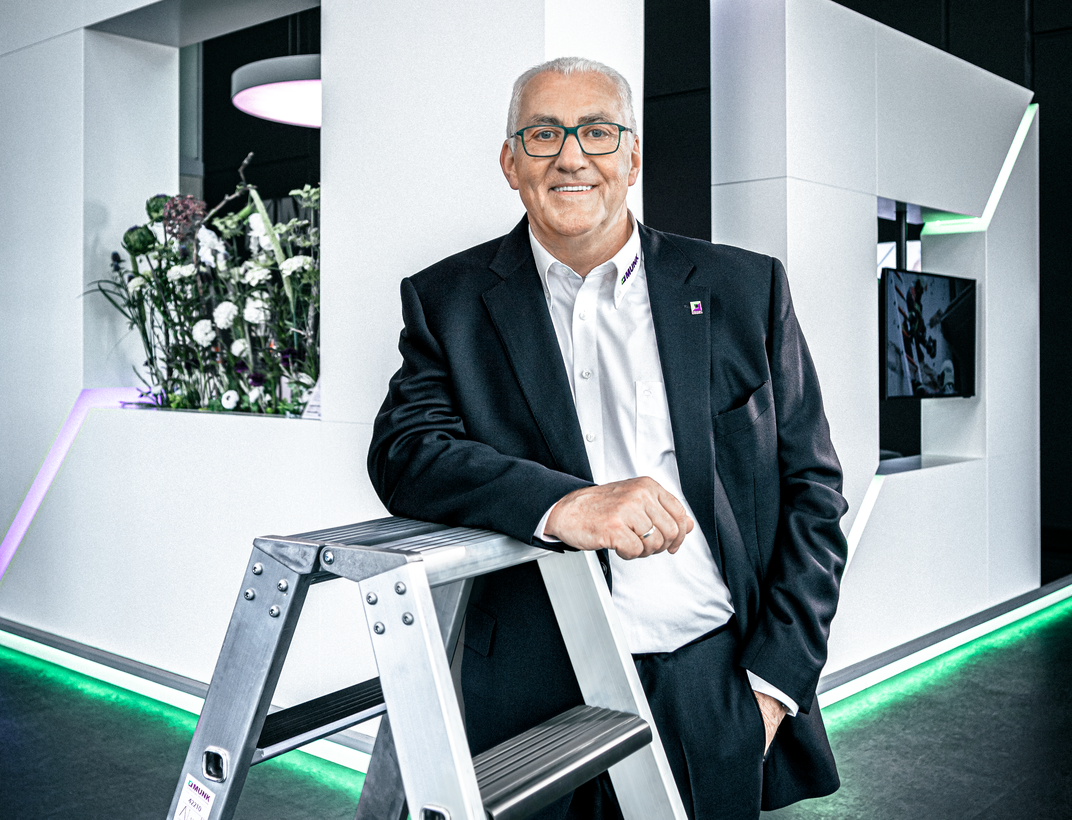

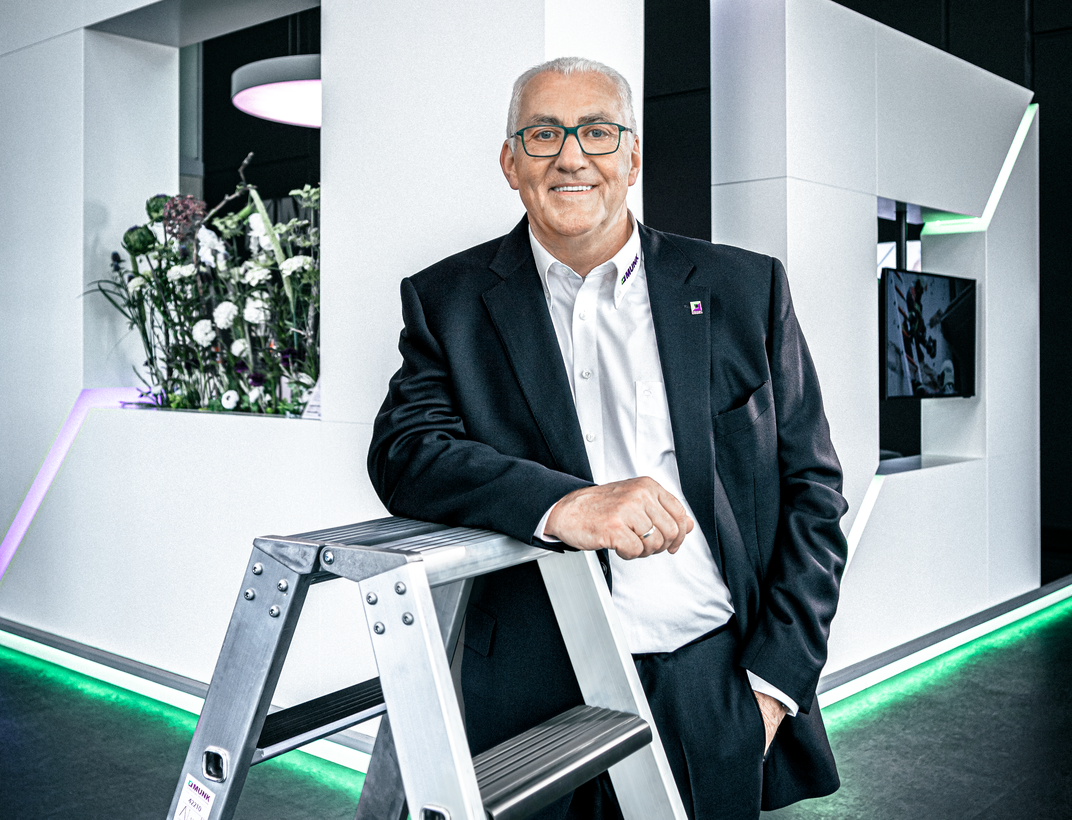

99 per cent of all companies in Germany are SMEs and very few have achieved what the Munk Group, based in Günzburg and Leipheim, is now celebrating: the family-run company, which is now in its fourth generation and managed by owner and Managing Director Ferdinand Munk, is now entering its 125th anniversary year. Originally founded as a wainwright's workshop and soon specialising in the manufacture of fire service and garden ladders, the Munk Group has developed over generations to become a technology and innovation leader in access technology and mobile container solutions. Today, the company has more than 2,500 products in its standard range and also stands for highly customised access and rescue technology solutions for every industry and every challenge. The Munk Group employs over 450 people in its home region, has over 20 sales partners worldwide and has always manufactured exclusively ‘Made in Germany’.

‘For 125 years, professionals in trade, industry and aid and rescue organisations have relied on us - and we have relied on them: We listen carefully and pay attention to even the smallest details during product development in order to offer them maximum safety and optimum functionality day after day at work or in the field. Over the generations, we have earned the trust of specialists and an excellent reputation as a reliable and innovative partner for users. I am very proud of this,’ says Ferdinand Munk. The owner and Managing Director of the Munk Group has two reasons to be happy: Ferdinand Munk and his wife Ruth Munk - also a long-standing Managing Director - have now been honoured with the special award for lifetime achievement at the Grand Prix for Small and Medium-Sized Enterprises.

The company is planning many events and activities for its anniversary year. The starting signal was given with the Munk Day at Legoland Deutschland Resort: at the exclusive park opening for the Munk Group, all 450 employees and their families were invited to experience the WinterWonder Legoland with all its attractions.

Safety. Made in Germany.

For Munk, a central pillar of his company's long success story is the guiding principle ‘Safety. Made in Germany": Since its foundation 125 years ago, the Munk Group has manufactured exclusively in its home region. In this way, the company keeps its supply chains stable and secure and also responds particularly quickly to customer enquiries and requirements. The high level of vertical integration on site also enables the Munk Group to offer a guarantee of 15 years on the entire series range made in Germany, which is unique in the industry.

‘Whether for trade and industry, emergency and rescue services or the public sector: professionals from all sectors trust our solutions more than ever, because we offer the right product for every user. ‘Safety. Made in Germany’ is more than just a claim - it is our mission and our promise to our customers. Because people who work with our innovations must be able to rely on maximum occupational safety at all times. After all, nothing less than their health depends on it,’ says Munk.

The Munk Group has long been regarded as a pioneer for regional production: in 2010, Munk was the first company ever to be awarded the certified ‘Made in Germany’ certificate of origin by TÜV Nord.

Committed to growth

The company's development is impressive: since Ferdinand and Ruth Munk started the fourth generation of the family at the Günzburg site in 1982, the total area has grown from 7,000 m2 to 200,000 m2. Annual turnover has increased almost 680-fold in 43 years, from DM 250,000 to around 85 million euros.

‘I can only thank everyone from the bottom of my heart who has travelled this path with our family and contributed so much to our success - above all, of course, our ever-growing team in Günzburg and Leipheim. We want to continue to be present as a company that takes responsibility. This applies to social responsibility as well as responsibility towards nature. That is why we have further expanded our sites in recent years with investments totalling over 30 million euros and will continue to invest tens of millions in the coming years - especially with regard to sustainable management,’ says Munk.

Green energy for production

Among other things, the investments are being channelled into a transformation concept for the energy supply, with which the Munk Group is becoming more and more energy self-sufficient and striving for CO2 neutrality ‘under its own steam’, i.e. without compensation measures: Following the latest innovations at the sites in Günzburg and Leipheim, Munk now covers 40 per cent of its own electricity requirements from its own photovoltaic systems and is even completely energy self-sufficient on sunny days. With a new wood chip system, Munk has also reduced its natural gas consumption for heating energy by 40 per cent. ‘We are already saving over 540 tonnes of CO2 every year. Our photovoltaic systems and the new wood chip system make an important contribution to this,’ says Alexander Werdich, also Managing Director.

Munk's own climate forest at the Leipheim site also binds CO2 in the long term and, with its climate-adapted tree species, makes a further contribution to a future worth living.

The family at the centre

As a family-run company, the Munk Group attaches particular importance to the compatibility of family and job and is constantly developing its family- and employee-friendly management concept: Munk employees and their families benefit from childcare programmes at the Munk Kids Club during the holidays as well as training and further education, which their family members can also take advantage of. The fact that the Munk Group is one of the most family-friendly employers in the German SME sector is also confirmed by the ‘Work and Family’ audit certificate: in 2022, Munk was the first company in the district of Günzburg to be awarded the quality seal of berufundfamilie Service GmbH.

With a doer mentality to the top

The maker gene seems to run in the family's blood: Ferdinand Munk's great-grandfather Leopold founded the family business in 1899, at that time still as a wainwright's workshop. He soon specialised in the manufacture of wooden ladders and was awarded the gold medal for his invention of a garden ladder at the Munich Trade Fair in 1925. Under grandfather Ludwig Munk, the company specialised in the manufacture of fire service, house and garden ladders from 1948. Ludwig Munk travelled from place to place on his motorbike and presented his newly developed extendable fire ladder to the local fire brigades. ‘With his mobile presentations, he practically laid the foundation for today's very popular roadshow product demonstrations,’ says Ferdinand Munk.

From 1974 onwards, Ferdinand Munk's father Leopold significantly developed the machinery and product range; under his leadership, the company became the leading fire equipment supplier in the region. Ferdinand and Ruth Munk jointly founded Günzburger Leiternbau in 1982, specialising in ladders made of aluminium, steel and stainless steel as well as rolling and folding scaffolding.

Munk Group: One family. One name. One mission.

After the sudden death of his father in 1991, Ferdinand Munk also took over his father's company and soon afterwards founded the special construction department for customised access technology solutions according to customer requirements. In 1993, the two companies became ‘Günzburger Steigtechnik’. The mission: To offer customers high-quality, sophisticated products with real added value as a technology and innovation leader. For example, in 2005 with the movable nivello ladder shoe or from 2010 with mobile containers for fire, rescue and disaster operations.

From then on, the company continued to expand and took the next step towards a successful future in 2021: in order to utilise the full potential in all business areas, the company reorganised itself as a group of companies under the umbrella of the Munk Group. At the same time, the Munk Rescue Technology division moved into its own location in the new plant in nearby Leipheim to accommodate the ever-increasing growth.

With the family name in the company name, the company has been sending out a clear signal ever since: ‘Whether it's Munk Günzburger Steigtechnik, Munk Rettungstechnik, Munk Service or Munk Profiltechnik: everyone should see that we, the Munk family, take responsibility for the company and its employees. It's not for nothing that we Munks say: one family, one name, one mission,’ says Ferdinand Munk. All of Ferdinand and Ruth Munk's daughters and sons-in-law are active in the company. Thanks to the dual leadership of Ferdinand Munk and son-in-law Alexander Werdich, the company is now managed by the fourth and fifth generation of the Munk family.

Further information on the Munk Group's anniversary year can be found at www.munk-group.com/en/125-years